-

+86-13362601721

-

Houwayu Industry Zone, Daxi Town, 317525, Wenling City, Zhejiang Province, China

Driven by technological innovation, we deliver efficient and reliable water pumps that empower a better quality of life.

Houwayu Industry Zone, Daxi Town, 317525, Wenling City, Zhejiang Province, China

The global pump industry is entering an unprecedented "green race."

From energy-efficiency standards and carbon-emission regulations to rising end-user utility costs, pump technologies are rapidly evolving toward higher efficiency, smarter control, and stronger sustainability. By 2026, the race for energy efficiency will hit a turning point. Companies that keep pace with regulatory changes and genuinely reduce energy costs will lead the market.

01 | Why Must the Pump Industry "Go Green" Before 2026?

Across Europe, China, the Middle East, and the Americas, energy-efficiency regulations are driving the technical upgrade of pump manufacturing.

Global data highlights one truth: Pumps consume massive energy.

In short:

High-efficiency pumps are no longer optional—they are essential for industry survival.

02 | Three Technologies That Will Define the Next 3 Years

Based on global policy roadmaps and market trends, the upcoming competition will focus on the following three technologies:

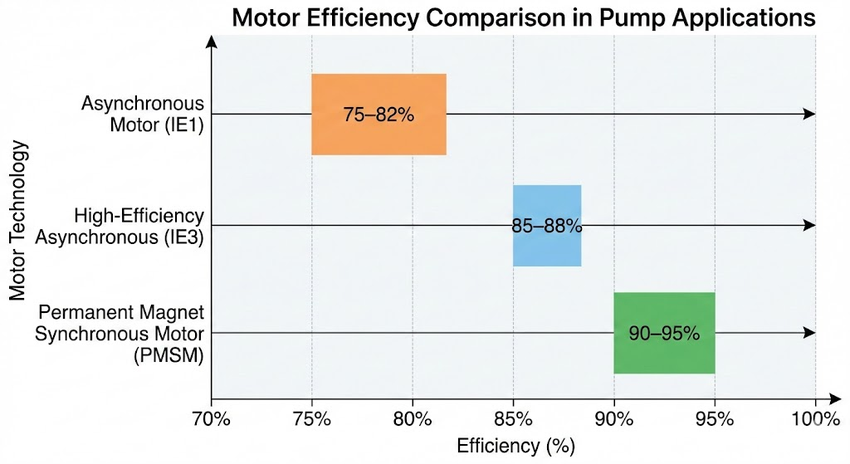

① High-Efficiency Motors

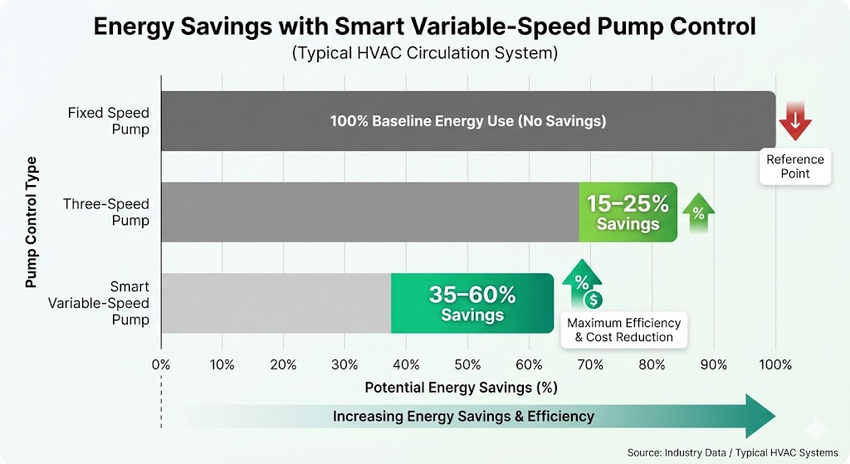

② Intelligent Variable-Speed Control

③ Energy-Optimized Hydraulics

03 | Industry Charts

Motor Efficiency Comparison:

Energy Savings from Smart Control (HVAC System):

04 | Our Strategy: High-Efficiency Motors + Smart Control

As a manufacturer of circulation and booster pumps, #LIXINGPROPUMP aligns its R&D strategy with global energy-efficiency trends:

PMSM High-Efficiency Motors

Intelligent Variable-Speed Control

Compliance with Global Standards

We believe the next-generation pump will be a motor + control system, not just a single component upgrade.

05 | How OEMs and Engineering Contractors Can Reduce Energy Costs

High-efficiency pumps offer measurable financial benefits, not just environmental advantages.

✔ For OEMs

✔ For Engineering Contractors & Building Projects

Ultimately, energy efficiency reduces the total cost of ownership (TCO).

Conclusion: Who Will Win the Green Race in 2026?

The answer is clear:

Those who lead in efficiency, intelligence, and long-term stability.

Those who help customers genuinely reduce system energy costs.

This is not just a technological race—

It is the future value competition of the entire pump industry.

Looking for:

Contact the LIXINGPROPUMP team and stay ahead in the industry’s green race.

Copyright © Taizhou Lixing Pump Co., Ltd. All Rights Reserved — Privacy Policy — Blog